- Track your orders

- Save your details for express checkout

Articles

New AA Auto Centre in Takanini: A Coordinated Fit-Out Success Story

When you're working with multiple contractors, how do you deal with the stress and a strict budget?

Case Overview

Challenge: Launching a new auto centre is often a high-pressure process. Between coordinating trades, managing timelines, and staying within budget, the risk of delays and overspending is real. AA’s new Takanini site was no exception.

They needed a full workshop fitout—from layout planning to equipment install—delivered on time and ready to go. With multiple contractors involved, the challenge was to keep everything aligned and efficient, without compromising on quality or future scalability.

Client: AA Takanini

Nature of Business: Auto Servicing Centre offering mechanical services, WOF certifications, battery services and more.

Solution: A staged equipment rollout featuring high-performance Steiner gear, coordinated with building works and tailored for maximum workshop efficiency and long-term growth.

The Challenge

AA was preparing to launch a new Auto Centre in Takanini, designed to serve a broad customer base including passenger vehicles and light commercials. The challenge was to:

- Design a workshop layout that supported high throughput and technician efficiency

- Deliver essential equipment within a startup budget

- Coordinate with trades to ensure seamless installation

- Ensure the site was fully operational by opening day

The Solution

Treadway was engaged to manage the full equipment fit-out in collaboration with the builder, TPW.

Stage One: Planning

We worked closely with Teejay and Garry from AA to develop a staged fit-out plan that aligned with their budget and operational goals. The process included:

- Budget-conscious staging

- Choosing the equipment

Budget-Conscious Staging

Stage One was scoped to meet startup needs.

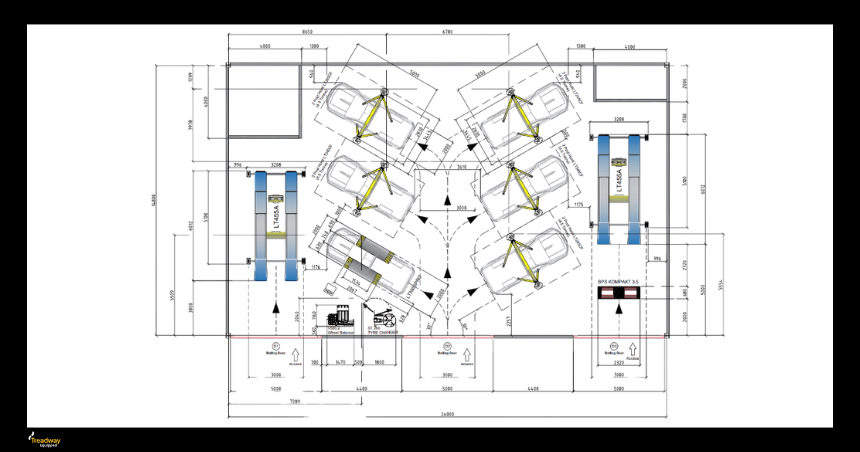

We created a long-term layout plan to optimise space and workflow. The design included hoist placement, tyre and wheel service zones, and access points for efficiency and safety.

We prioritised essential equipment that would deliver immediate value while allowing for future expansion.

To optimise the new workshop’s space, we came up with the following layout:

Choosing the Equipment

For this layout, we recommended our ever-reliable Steiner range.

Below, we break down how each piece of equipment maximises AA Takanini’s investment.

1. Steiner LT455A Four-Post Alignment Hoist

A drive-on four-post hoist designed for wheel alignment and general servicing. Built to handle heavier vehicles with precision and safety.

Key Features:

- 5.5-tonne lifting capacity – Suitable for light commercials, SUVs, and larger passenger vehicles

- Adjustable turn plate positions – Accommodates varying wheelbases for accurate alignment setups

- Electro-air control system – Enhances operator safety and allows precise vehicle positioning

- Dual safety locking mechanisms – Provides layered protection at every lift height

- Cable-driven hydraulic system – Ensures smooth, consistent lifting with minimal maintenance

- Integrated rolling jack – Enables underbody work without repositioning the vehicle

- Skid-proof diamond platform – Improves grip and safety during drive-on and lift operations

- Adjustable platform and safety lock ladders – Supports varied vehicle profiles and secure locking

Benefits:

- Supports both alignment and general servicing

- Accommodates a wide range of vehicles including light commercials

- Enhances technician safety and workflow

- Handles larger vehicles, expanding service capability

- Drive-on design speeds up job setup, increasing daily throughput

Why This Is Perfect for a Startup:

Combines alignment and general servicing in one unit. It’s a space-saving, revenue-generating solution that’s easy to install and operate—ideal for new workshops looking to offer premium services without overextending their budget or floor plan.

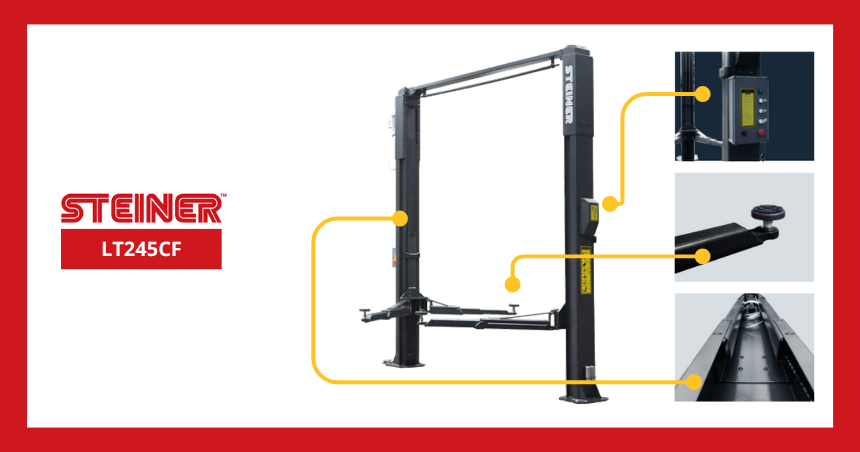

2. Steiner LT245CF Two-Post Clear Floor Hoists

A high-capacity two-post hoist designed for general mechanical servicing. Its clear-floor design improves technician mobility and bay efficiency, making it a staple for any high-throughput workshop.

Key Features:

- 4.5-tonne lifting capacity – Handles a wide range of vehicles, from compact cars to light commercials

- Ezi-reach three-stage asymmetrical arms – Provides balanced lifting and flexible reach for varied vehicle sizes

- Clear-floor design – Allows unobstructed movement of tool trolleys and creepers

- Direct-drive hydraulic cylinders with electro-magnetic locks – Ensures smooth, safe lifting with minimal maintenance

- Built-in vehicle protection – Includes a padded overhead bar and rubber door guards

- Height adaptors included – Accommodates vehicles with higher lift points

- Simple push-button operation – Streamlines technician workflow

Benefits:

- Supports a wide range of vehicles, increasing service versatility

- Clear-floor design improves technician mobility and workflow

- Durable build reduces downtime and long-term maintenance costs

Why This Is Perfect for a Startup:

The LT245CF is a reliable workhorse for general servicing. Its clear-floor design improves technician access and safety, while the robust build supports consistent, high-volume use. The combination of strength, safety, and ease of use makes it ideal for workshops aiming to maximise bay efficiency and technician productivity.

3. Steiner LT300S Full-Rise Scissor Lift

A compact, surface-mounted scissor lift designed for tyre, brake, and underbody work. Operates on single-phase power, making it easy to install in standard workshop environments.

Key Features:

- 3-tonne lifting capacity – Suitable for most passenger vehicles

- Full-rise height – Allows technicians to work comfortably standing

- Low-profile, surface-mounted design (115mm closed height) – No need for floor recesses

- Dual hydraulic cylinders with automatic safety locks – Ensures level lifting and safe operation

- Fully electric control system – No air required, simplifying setup and maintenance

- Hydraulic equalisation between platforms – Provides smooth ramp access and balanced lifting

- Adds service capacity without structural changes

- Surface-mount design avoids costly floor recesses

- Single-phase power simplifies installation in standard commercial spaces

- Reduces installation costs and setup time

- Maximises bay usage with minimal space requirements

- Ideal for high-frequency, short-duration jobs that drive daily revenue

- Easy to relocate or upgrade as the business grows

Why This Is Perfect for a Startup:

This lift adds a dedicated bay for quick-turnaround jobs without requiring floor recesses or three-phase power. It’s easy to install, relocate, and scale—perfect for startups needing flexibility and fast ROI from high-frequency services like tyres and brakes.

4. Steiner ST260 Tyre Changer

A heavy-duty tyre changer built for speed, safety, and compatibility with modern tyre profiles—including run-flats and low-profile tyres.

Key Features:

- Variable torque bead breaker – Suitable for RSC and run-flat tyres

- Wide clamping range – can handle 11” to 24” rims from the outside

- Durable steel frame and stainless steel cylinder – Built for high-volume use

- Optional helper arms and motorcycle adaptors – Expand service capability

Benefits:

- Handles modern tyre profiles with ease

- Reduces technician strain and training time

- Speeds up tyre changes for higher service volume

Why This Is Perfect for a Startup:

Tyre services are a fast way to generate revenue. Its compatibility with modern tyres makes it a future-proof investment, while optional accessories allow startups to expand into niche services like motorcycle tyres.

5. Steiner ST420 Wheel Balancer

A compact, precision wheel balancer designed for fast, accurate results with minimal operator input—ideal for high-volume tyre bays.

Key Features:

- High-speed balancing cycle – reduces balancing time

- Italian design and software – high-precision tech provides long-term functionality

- Automatic data entry and digital display – Speeds up workflow and reduces errors

- LED wheel illumination and foot brake – Improves visibility and control during balancing

- Optimisation and weight split functions – Ensures precise balancing

- Suitable for different tyre models – accommodates passenger car, motorcycle and SUV tyres, with optional motorcycle adaptor for motorcycle wheel balancing

- Haweka clamping system – Delivers long-term accuracy and reliability

Benefits:

- Delivers fast, accurate balancing for smoother rides and longer tyre life

- Automatic data entry reduces operator error and speeds up workflow

- Compact design fits into tight bays, maximising space

Why This Is Perfect for a Startup:

Precision and speed help build customer trust. The ST420 offers both, with a small footprint and user-friendly interface—perfect for startups wanting to deliver professional-grade results without overinvesting.

Stage Two: Seamless Coordination and Installation

Stage two involved working with the builder, TPW, to integrate the installation and testing with their construction schedule.

We collaborated with TPW to align our electrical requirements and installation timeline with building works, electrical, and floor painting, ensuring a smooth and efficient process for both the builder and the client.

This helped minimise project duration, eliminate potential reworks, and most importantly, keep the targets on schedule and the project within budget.

We also gained new friends from TPW!

Stage Three: Post-Installation Training and Ongoing Support

To ensure AA Takanini’s team is ready for launch, we scheduled team training sessions to orient them on each equipment we installed.

This helped take the load off the management team, allowing them to focus on preparing for the opening.

Why we include post-installation training in our fit-outs:

- Reduces technician onboarding time

- Minimises operational errors and equipment misuse

- Ensures long-term performance and ROI from every product

- In addition to the training, Treadway Equipped offers ongoing after-sales support, assuring AA Takanini will receive the help they need when they need it.

The Results

LT455A 4-post alignment hoist

Smart choices at startup lead to long-term gains.

With their recent installation, AA Takanini is able to offer the following services on site:

- Warrant of Fitness (WOF)

- General vehicle repair

- Oil change

- Cambelt replacement

- Battery services

- Car servicing

- AA pre-purchase inspections

- AA 10-point checkup

LT245CF Two-Post Clear Floor Hoists

As part of the trusted AA network, AA Takanini is built to deliver the level of service customers expect—and the equipment we supplied plays a key role in helping them meet that standard from day one.

LT300S Full-Rise Scissor Lift, ST260 Tyre Changer and ST420 Wheel Balancer

Built Without the Headaches

At Treadway Equipped, we’re always ready to help plan your growth. Whether you’re building a startup or expanding, our team is equipped to help run your project as frictionless as possible.

If you're facing the same challenge—tight timelines, limited resources, and too many moving parts—we can help you open your doors with confidence.

Call us now to explore workshop solutions.